How Does EI Transformer Factory Shape Nbcbdz Solutions

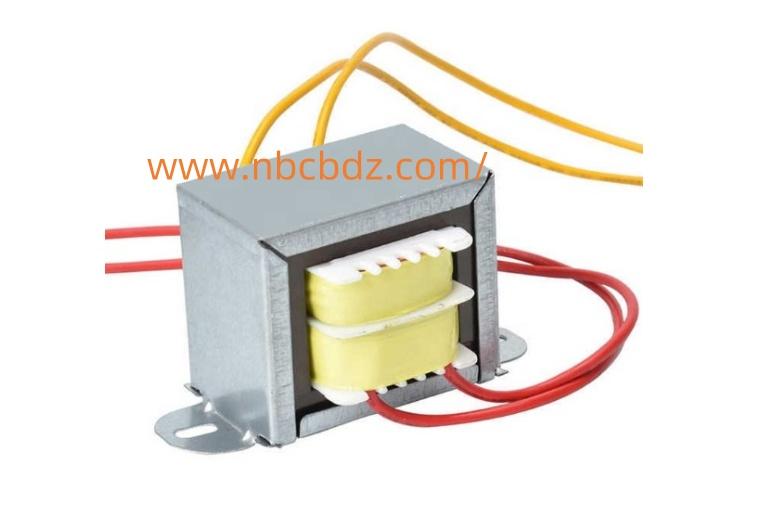

In many production environments, the relationship between EI Transformer Factory expertise and the standards pursued by Nbcbdz reflects a steady demand for durable, consistent, and precisely manufactured components. This connection highlights how dependable transformer construction supports a wide range of electrical applications without relying on inflated claims or exaggerated performance language.

A reliable transformer is often the result of balanced engineering decisions. Core geometry, coil arrangement, and insulation planning must work together to maintain stable operation. When each element is handled with care, equipment can deliver predictable performance under common operating conditions. In an industry where predictability matters, builders often focus on process discipline, controlled material selection, and practical testing routines rather than dramatic technological statements.

Industrial buyers typically prioritize stable output, noise control, and compatibility with existing systems. These preferences influence design considerations, encouraging manufacturers to pursue structural clarity and well-defined production stages. In many cases, attention to manageable tolerances and practical winding techniques reduces unnecessary complexity while keeping the final component suitable for integration into broader systems.

Another point often evaluated by decision-makers is long-term maintainability. Transformers built with orderly assembly methods and accessible layouts can support easier inspection cycles. This aids environments where downtime carries significant cost, making structured assembly and consistent documentation appealing traits for purchasers who value smooth operation.

Supply planning also plays a crucial role. Predictable delivery schedules, steady material sourcing, and transparent communication help ensure that electrical projects progress without avoidable interruption. Manufacturers focusing on these aspects often gain trust not through bold claims, but by meeting reasonable expectations with clarity and continuity.

For organizations evaluating transformer options, examining process quality, material steadiness, and application fit can provide a grounded basis for selection. Each project presents its own constraints, and a thoughtful review of operational requirements often leads to choices that suit both immediate and long-term goals.

If you are considering components for upcoming plans, let your next step be a small curiosity. Follow the path to https://www.nbcbdz.com/product/ and see what aligns with your needs.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness