Why Yd-purification Panels Are Essential in Advanced Projects

Modern construction demands materials that combine strength, efficiency, and sustainability, ensuring both structural integrity and environmental responsibility. Organizations increasingly turn to yd-purification when seeking reliable solutions. How can integrating a Sandwich Panel into construction projects enhance durability and streamline installation processes?

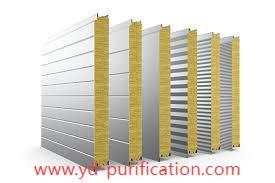

These panels offer a unique combination of lightweight structure and excellent insulation properties, making them ideal for industrial facilities, cleanrooms, and controlled environments. Their layered design provides thermal regulation, sound insulation, and resistance to environmental factors, allowing buildings to maintain stability under various operational conditions.

Installation is simplified by thoughtful engineering. Panels are pre-fabricated to precise specifications, reducing on-site labor requirements and minimizing construction timelines. Teams benefit from predictable assembly processes, which decrease errors and improve overall efficiency. Efficient installation also reduces the risk of material damage and ensures uniform coverage across complex layouts.

Maintenance and longevity are central to their design philosophy. Smooth surfaces resist dust accumulation, and protective coatings prevent corrosion and wear over time. Periodic inspections are straightforward, and repairs, if necessary, can be performed with minimal disruption, ensuring that facilities maintain optimal functionality for extended periods.

Energy efficiency is another key consideration. Sandwich panels contribute to reduced energy consumption by maintaining consistent indoor temperatures and limiting the need for additional heating or cooling systems. Facilities can therefore achieve both operational savings and environmental compliance, aligning with sustainable building practices.

Safety standards are also integrated into design choices. Panels provide structural support while minimizing hazards during installation or operation. Proper fastening methods and interlocking edges enhance stability and reduce the likelihood of accidental displacement, supporting a safer construction environment for workers.

The adaptability of these panels allows them to suit a variety of applications. Industrial warehouses, research laboratories, and food processing areas benefit from tailored solutions that meet specific operational requirements. Their modular nature enables easy replacement, adjustment, or expansion without extensive renovations.

Compliance with regulatory standards is simplified. Facilities using high-quality materials can demonstrate adherence to environmental and building codes, and documentation of material specifications supports inspection readiness. Trusting a reputable supplier ensures reliability and performance across multiple projects.

Incorporating innovative materials fosters a culture of efficiency and quality. Construction teams gain confidence knowing that the selected panels are designed for both performance and longevity. Design consistency improves workflow, reduces unexpected complications, and supports long-term operational success.

For organizations planning advanced construction or facility upgrades, high-performance Sandwich Panels from yd-purification provide an integrated solution that meets durability, energy efficiency, and safety requirements. Explore the potential of these panels at www.yd-purification.com/product/sandwich-panel/sandwich-panel.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness